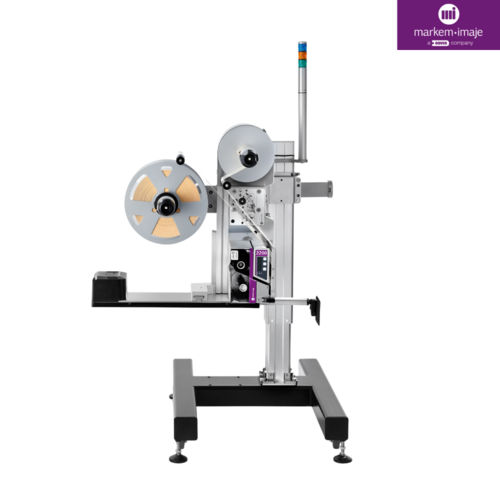

Markem Imaje 2200 Print and Apply labeling machines

Markem Imaje 2200 Print and Apply labeling machines Specification

- Working Temperature

- 5C to 40C

- Cabinet Material

- Stainless steel

- Interface

- Ethernet, USB, Serial RS232, Parallel

- Print Speed

- Up to 125 mm/s

- Print Technology

- Thermal transfer and direct thermal

- Function

- Label printing & automated application

- Power Supply

- AC mains, built-in power adapter

- Weight

- Approx. 40 kg

- Capacity

- Can print/apply up to 100 labels per minute

- Features

- Real-time variable data printing, robust design, easy integration, quick change label roll, operator-friendly interface, large display

- Usage & Applications

- Case, pallet, tray, and product labeling in industrial environments

- Processor Type

- Embedded industrial-grade microprocessor

- Processor Speed

- High-speed processing for fast labeling

- Noise Level

- Less than 70 dB

- Humidity %

- 10% to 90% non-condensing

- Condition

- New

- Material

- Stainless steel and industrial-grade components

- Dimensions

- 650 mm x 500 mm x 400 mm (L x W x H)

- Gross Power

- 150 W

- Voltage

- 110-240V AC

- Automatic Grade

- Automatic

- Color Print Speed

- Up to 125 mm/s

- Black Print Speed

- Up to 125 mm/s

- Maximum Paper Size

- Up to 150 mm (label width)

- Maximum Resolution

- 300 dpi

- Use

- Print and apply labels on packaging

- Label Roll Capacity

- Up to 400 mm diameter

- Print Head

- Replaceable high-resolution thermal print head

- Mounting Options

- Floor, conveyor, overhead, side application

- Display Type

- Graphical operator display

- Maximum Label Length

- Up to 300 mm

- Media Sensor

- Automatic label and ribbon detection

- Supported Barcode Types

- EAN, UPC, Code 128, QR Code, Data Matrix, and others

- Languages Supported

- Multiple (English, Spanish, German, French, Italian, etc.)

- Maintenance Features

- Tool-less printhead change, easy access for cleaning

- Compliance

- CE, RoHS, and other relevant certifications

- Communication Protocols

- TCP/IP, ZPL, SBPL, EasyCode, DPL compatible

- Network Integration

- Compatible with enterprise resource planning (ERP) systems

- Label Format Flexibility

- Supports various label sizes/shapes

- Safety Features

- Emergency stop, guarding, fault alarms

Markem Imaje 2200 Print and Apply labeling machines Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Markem Imaje 2200 Print and Apply labeling machines

Enhance your production line efficiency with the Markem-Imaje 2200 Series Industrial Labeler, designed to meet diverse case and pack labeling requirements. Engineered for reliability and ease of use, this series integrates cutting-edge technologies to ensure consistent, high-speed labeling without compromising on accuracy.

Challenges Addressed:

Streamline your labeling processes with minimal intervention, reducing downtime and operational errors. Whether you face complex labeling demands or require seamless integration with variable speed lines, the Markem-Imaje 2200 Series offers a versatile solution that adapts to your specific production needs.

Key Benefits:

Maximized Uptime: Minimize line stoppages and media change downtime with optimized label path and automatic features.

- High Performance: Achieve faultless traceability with ANSI grade A/B codes, even at high application speeds.

- Precision Labeling: The eTouch-Si applicator, enhanced with AI, ensures labels are applied accurately and safely at maximum production speeds.

- User-Friendly Interface: CoLOS based Production Interface allows intuitive operation and real-time data monitoring, enhancing operational efficiency and reducing errors.

Choose the Markem-Imaje 2200 Series for a robust labeling solution that optimizes your production capabilities while ensuring compliance and traceability across your product line.

Versatile Labeling Capabilities

The Markem Imaje 2200 series can handle various label sizes up to 150 mm wide and 300 mm long, supporting complex label shapes. Its advanced barcode technology accommodates EAN, UPC, Code 128, QR Code, Data Matrix, and more, making it ideal for diverse packaging needs across industries.

Superior Connectivity and Integration

Equipped with TCP/IP, ZPL, SBPL, EasyCode, and DPL protocols, the 2200 integrates smoothly into any ERP or industrial IT system. Multiple physical interfaces, including Ethernet, USB, serial RS232, and parallel, allow flexible installation and data exchange. Multi-language operator displays streamline workflows for global teams.

Reliable Performance and Easy Maintenance

Utilizing high-resolution thermal transfer and direct thermal technology, the 2200 achieves crisp print at speeds up to 125 mm/s and up to 100 labels per minute. It incorporates automatic label and ribbon detection, tool-free printhead changes, and emergency safety features, maximizing uptime and protecting operators.

FAQ's of Markem Imaje 2200 Print and Apply labeling machines:

Q: How does the Markem Imaje 2200 accommodate different label sizes and types?

A: The Markem Imaje 2200 supports a wide range of label formats, including various shapes and sizes up to 150 mm in width and 300 mm in length. Its flexible design, along with automatic label and ribbon detection sensors, ensures precise application across case, pallet, tray, and product labeling tasks.Q: What barcode types and printing technologies are compatible with this labeling system?

A: This machine handles popular barcode symbologies such as EAN, UPC, Code 128, QR Code, Data Matrix, and others. It uses both direct thermal and thermal transfer printing for high-resolution output at up to 300 dpi, enabling clear and durable barcode and text printing.Q: When should the print head be replaced, and how is maintenance managed?

A: Print head replacement is recommended when print quality declines. The 2200 simplifies maintenance with a tool-less printhead change design and easy access for routine cleaning, helping minimize downtime and ensure consistently high printing quality.Q: Where can the Markem Imaje 2200 be installed for optimal labeling?

A: The device supports versatile mounting options, including floor, overhead, conveyor, or side application. Its compact design allows for easy integration into existing packaging lines, optimizing label placement and workflow efficiency in various industrial settings.Q: What is the process for integrating the 2200 with my existing enterprise systems?

A: Integration is straightforward thanks to support for widely-used communication protocols like TCP/IP, ZPL, SBPL, EasyCode, and DPL. The machine connects via Ethernet, USB, serial RS232, or parallel interfaces, ensuring smooth data transfer with ERP or warehouse management systems.Q: How does the operator interface enhance usability and efficiency?

A: The graphical display supports multiple languages (English, Spanish, German, French, Italian, etc.), making operation intuitive. Operators benefit from real-time fault alarms, quick label roll changes, and easy menu navigation, increasing productivity for global teams.Q: What safety and compliance features are included with the machine?

A: The Markem Imaje 2200 features emergency stops, guarding, and real-time fault alarms to protect operators. It meets CE, RoHS, and other international standards, ensuring operational safety and environmental responsibility.

Price 800000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS